Hydrogen Steam Boiler Calculator

Size a hydrogen steam boiler

Steam Boiler Calculator Equations

Annual Steam Required

\[ Q_{steam} = D \times N_{days} \times H_{daily} \]

Where:

- \( D \) = Steam rate (ton/h)

- \( N_{days} \) = Annual operating days

- \( H_{daily} \) = Daily operating hours

Heat Required

\[ Q_{heat} = \frac{Q_{steam} \times 1000 \times (h_{steam} - h_{feed})}{3.6 \times 10^6} \]

Where:

- \( h_{steam} \) = Steam enthalpy (kJ/kg)

- \( h_{feed} \) = Feedwater enthalpy (kJ/kg)

- \( T_{feed} \) = Feedwater temperature (°C)

Annual Fuel Required

\[ Q_{fuel} = \frac{Q_{heat}}{\eta_{burner}} \]

Where:

- \( \eta_{burner} \) = Burner efficiency

Hydrogen Demand

\[ m_{H_2} = \frac{Q_{fuel}}{N_{days}} \times \frac{1000}{33.33} \times \frac{E_{H_2} \times f_{blend}}{E_{fuel} \times (1 - f_{blend}) + E_{H_2} \times f_{blend}} \]

Where:

- \( E_{fuel} \) = Fuel energy density (kWh/m³)

- \( E_{H_2} \) = Hydrogen energy density (kWh/m³)

- \( f_{blend} \) = Hydrogen blend fraction

Electrolyser Size

\[ P_{electrolyser} = \frac{m_{H_2} \times 39.44}{CF \times \eta_{electrolyser} \times H_{daily} \times 1000} \]

Where:

- \( CF \) = Capacity factor

- \( \eta_{electrolyser} \) = Electrolyser efficiency

📖 Variables Legend

| Symbol | Description | Unit |

|---|---|---|

| \( D \) | Steam rate | ton/h |

| \( P_{steam} \) | Steam pressure | barg |

| \( \eta_{burner} \) | Burner efficiency | % |

| \( f_{blend} \) | Hydrogen blend ratio | % vol |

| \( h_{steam} \) | Steam specific enthalpy | kJ/kg |

| \( CF \) | Electrolyser capacity factor | % |

| \( \eta_{electrolyser} \) | Electrolyser efficiency | % |

| \( Q_{steam} \) | Annual steam required | ton/year |

| \( Q_{heat} \) | Heat required | MWh |

| \( m_{H_2} \) | Hydrogen demand | kg/day |

| \( P_{electrolyser} \) | Electrolyser size | MW |

Hydrogen Stem Boilers: The Future of Industrial Heating

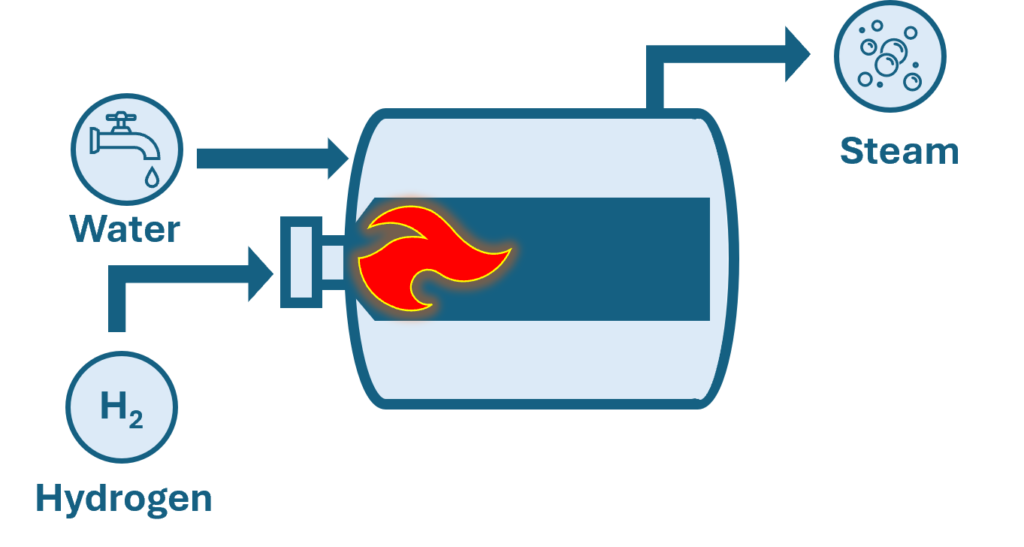

⚙️ How Hydrogen Boilers Work

Modern hydrogen-ready boilers use one of three approaches:

- • 100% Hydrogen Combustion: Specialized burners using H₂'s high flammability (4-75% in air)

- • Blended Fuels: Mix hydrogen with natural gas (20-30% H₂ in existing infrastructure)

- • Dual-Fuel Systems: Alternate between hydrogen and other fuels based on availability

💡 Key Advantage: Hydrogen boilers can achieve 95%+ efficiency when properly designed, compared to 85-92% for natural gas systems.

🌱 Why This Calculator Matters

Transition planning requires understanding:

- • Hydrogen demand vs storage capabilities

- • Infrastructure modification costs

- • Realistic emission reductions

- • Operational impact on steam output

Our tool helps answer:

"If I replace 30% of natural gas with green hydrogen, how does it affect my annual fuel costs and carbon footprint?"

⚠️ Critical Implementation Factors

Material Compatibility

Hydrogen causes embrittlement in standard steel pipes above 20% blends

Flame Speed Management

H₂ burns 7x faster than methane - requires modified burner geometry

NOx Tradeoffs

While CO₂ drops, hydrogen combustion can increase NOx by 50-200% without proper controls

📈 State of the Art (2024)

| Technology | Max H₂ Blend | TRL | Key Players |

|---|---|---|---|

| Retrofit Burners | 25% | 8-9 | Honeywell, Siemens |

| Dedicated H₂ Boilers | 100% | 6-7 | Mitsubishi, GE Vernova |

❌ Common Calculation Mistakes

- Ignoring hydrogen's lower volumetric energy density (3.54 kWh/m³ vs NG's 11.15 kWh/m³)

- Assuming linear efficiency gains with H₂ blending

- Overlooking compressor energy for H₂ storage

- Using LHV instead of HHV for electrolyser sizing

📋 Should You Switch? Decision Checklist

- ✅ Current natural gas price > $8/MMBtu

- ✅ Carbon tax > $50/ton CO₂

- ✅ On-site renewable energy available

- ❌ Existing boiler > 15 years old

- ❌ Steam demand varies > ±30% daily

Pro Tip: Start with 10-15% blending to test system compatibility before major retrofits.

© 2025 HowICalculate.com